Sharrë breziCORMAK

HBS275

Sharrë brezi

CORMAK

HBS275

çmim fiks plus TVSH

1 349 €

Viti i prodhimit

2025

Gjendje

I ri

Vendndodhje

Siedlce

Fotot tregojnë

Shfaq hartën

Të dhëna për makinën

Çmimi & Vendndodhja

çmim fiks plus TVSH

1 349 €

- Vendndodhje:

- Brzeska 120, 08-110 Siedlce, Polska

Telefononi

Detajet e ofertës

- ID e shpalljes:

- A16883691

- Përditësim:

- së fundmi më 07.01.2026

Përshkrim

CORMAK HBS275 band saw, equipped with a hydraulic cylinder, a cooling system and an arm swivelling up to 60º, together with blades from renowned German company Röntgen, is used commonly in ironworking, where precision, quality and cutting speed are essential.

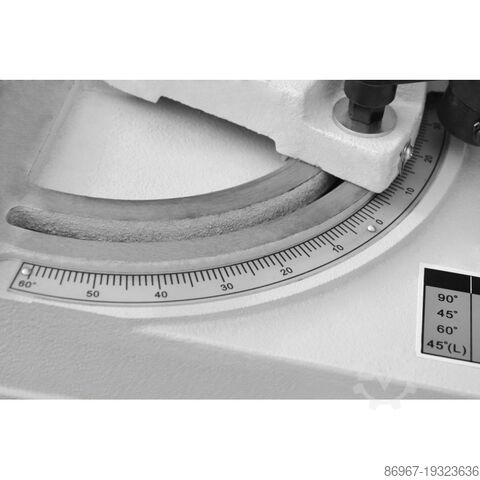

Horizontal band saw with a swivelling arm for cutting metals, allows for cutting in plane perpendicular to the axis of material cut and at any angle from 0 to 60º. Material for cutting can be fed manually or with any mechanical feeding device, with automatic tool feed. Band guides are equipped with dedicated carbide plates and bearings. This has a huge impact on band guiding, its durability, cut straightness, cutting accuracy and quality. Carbide guiding drastically reduces the wear of the machine and blades.

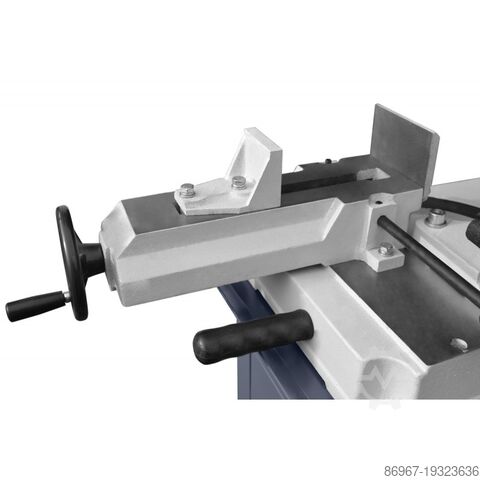

Machine's arm made of uniform cast iron as well as a 27 mm wide cutting band are capable of low and high quantity cutting of profiles and other materials. The vice is located in an adjustable bed, equipped with a quick clamp. Blade guides have cemented carbide plates and roller bearings. Its these cemented carbide guides that provide cut precision and straightness. The arm, positioned at an angle of 25º, thus increasing blade durability, is equipped with an automatic blade tension sensor. To the bottom of the arm a brush wire is attached, ensuring clean and functional brush. Machine's drive is transmitted through a worm drive. A 3-phase motor with 2 cutting speeds and motor thermal protection. This cutting machine also has a strain gauge - a band tension sensor and an automatic switch-off in case the cutting band breaks. Upper part of the base constitutes a tank for flood coolant draining and chips produced during cutting. A cast iron workbench is attached to the base, with a swivel arm and control panel on separate arm.

The main cutting move in the cutting process is moving the cutting band and the arm lowering feed. The arm lowering speed (the cutting speed) is adjusted with the hydraulic cylinder. The feed speed is controlled by the control panel. There are 2 cutting band speeds to choose from: 37.5 and 75 m/min. In rest arm position (after the cutting process) the cutting band drive is switched off automatically. Safety is ensured with cutting band guards and microswitches stopping the motor after cutting cycle is finished or after any of the guards are opened; additional protection consists of automatic switch-off of the band saw in case the cutting band breaks.

Technical data

Total power

1.5 kW

Power supply

400V 50Hz

Arm lowering control

hydraulic cylinder

Band dimensions

2455 x 27 x 0.9 mm

Band speed

37.5/75 m/min

Vice base height

900 mm

Weight

215 kg

Angle

0º

Iedpfx Aeudi Unjd Tjht

ø220

260 x 140

200 x 200

45º R

ø160

160 x 140

160 x 160

60º R

ø100

120 x 100

100 x 100

Horizontal band saw with a swivelling arm for cutting metals, allows for cutting in plane perpendicular to the axis of material cut and at any angle from 0 to 60º. Material for cutting can be fed manually or with any mechanical feeding device, with automatic tool feed. Band guides are equipped with dedicated carbide plates and bearings. This has a huge impact on band guiding, its durability, cut straightness, cutting accuracy and quality. Carbide guiding drastically reduces the wear of the machine and blades.

Machine's arm made of uniform cast iron as well as a 27 mm wide cutting band are capable of low and high quantity cutting of profiles and other materials. The vice is located in an adjustable bed, equipped with a quick clamp. Blade guides have cemented carbide plates and roller bearings. Its these cemented carbide guides that provide cut precision and straightness. The arm, positioned at an angle of 25º, thus increasing blade durability, is equipped with an automatic blade tension sensor. To the bottom of the arm a brush wire is attached, ensuring clean and functional brush. Machine's drive is transmitted through a worm drive. A 3-phase motor with 2 cutting speeds and motor thermal protection. This cutting machine also has a strain gauge - a band tension sensor and an automatic switch-off in case the cutting band breaks. Upper part of the base constitutes a tank for flood coolant draining and chips produced during cutting. A cast iron workbench is attached to the base, with a swivel arm and control panel on separate arm.

The main cutting move in the cutting process is moving the cutting band and the arm lowering feed. The arm lowering speed (the cutting speed) is adjusted with the hydraulic cylinder. The feed speed is controlled by the control panel. There are 2 cutting band speeds to choose from: 37.5 and 75 m/min. In rest arm position (after the cutting process) the cutting band drive is switched off automatically. Safety is ensured with cutting band guards and microswitches stopping the motor after cutting cycle is finished or after any of the guards are opened; additional protection consists of automatic switch-off of the band saw in case the cutting band breaks.

Technical data

Total power

1.5 kW

Power supply

400V 50Hz

Arm lowering control

hydraulic cylinder

Band dimensions

2455 x 27 x 0.9 mm

Band speed

37.5/75 m/min

Vice base height

900 mm

Weight

215 kg

Angle

0º

Iedpfx Aeudi Unjd Tjht

ø220

260 x 140

200 x 200

45º R

ø160

160 x 140

160 x 160

60º R

ø100

120 x 100

100 x 100

Ofrues

Shënim: Regjistrohuni falas ose hyni, për të parë të gjitha informacionet.

Dërgo kërkesë

Telefon & Faks

+48 25 63... njoftime

Këto njoftime mund t'ju interesojnë edhe ju.

Njoftim i vogël

Gjermania

Gjermania

1 286 km

Makinë formësuese - Vertikale

RAVENSBURGS 250

RAVENSBURGS 250

Njoftim i vogël

Borken

Borken

1 378 km

Gjenerator

SDMO

SDMO

Njoftim i vogël

Schlüchtern

Schlüchtern

1 313 km

LATHE

Voest AlpineDA 160

Voest AlpineDA 160

Njoftim i vogël

Siedlce

Siedlce

1 235 km

Sharrë brezi

CORMAKBS-128HDRC 400V

CORMAKBS-128HDRC 400V

Njoftim i vogël

Gjermania

Gjermania

1 286 km

Torno qendrore dhe torno gishti

STRUNGURI ARADSN501x1500

STRUNGURI ARADSN501x1500

Njoftim i vogël

Mindelheim

Mindelheim

1 082 km

Sharrë bande

MIOTAL®S 170 G

MIOTAL®S 170 G

Njoftim i vogël

Wien

Wien

840 km

Makinë saldimi

FRONIUS TPS 5000 MIG MAG PULSTRANS PULS SYNERGIC 5000 / 500 MASCHINE

FRONIUS TPS 5000 MIG MAG PULSTRANS PULS SYNERGIC 5000 / 500 MASCHINE

Njoftim i vogël

Pöllau bei Hartberg

Pöllau bei Hartberg

767 km

Sharrë me bandë për metal të përdorur Hans Schreiner MBS270

Hans SchreinerG-ME132214P

Hans SchreinerG-ME132214P

Njoftim i vogël

Wiesbaden

Wiesbaden

1 359 km

Stërvitje shtyllash

IXIONBSS-23 AV

IXIONBSS-23 AV

Njoftim i vogël

Böblingen

Böblingen

1 214 km

Sharrë bande

ZIMMERZ 241-1/R

ZIMMERZ 241-1/R

Njoftimi juaj u fshi me sukses

Ndodhi një gabim