Makinë mbushëse me ujë, vaj, sapun, AdBluePROTON EE-ELEKTRONIKA d.o.o

XFR1000

Makinë mbushëse me ujë, vaj, sapun, AdBlue

PROTON EE-ELEKTRONIKA d.o.o

XFR1000

Viti i prodhimit

2025

Gjendje

I ri

Vendndodhje

Šašinovec

Fotot tregojnë

Shfaq hartën

Të dhëna për makinën

- Përshkrimi i makinës:

- Makinë mbushëse me ujë, vaj, sapun, AdBlue

- Prodhues:

- PROTON EE-ELEKTRONIKA d.o.o

- Model:

- XFR1000

- Viti i prodhimit:

- 2025

- Gjendje:

- i ri

- Funksionalitet:

- plotësisht funksionale

Çmimi & Vendndodhja

- Vendndodhje:

- Krcevina 4, 10360 Soblinec, Hrvatska

Telefononi

Detaje teknike

- Gjerësia totale:

- 2 400 mm

- Gjatësia totale:

- 15 000 mm

- Lartësia totale:

- 2 800 mm

- Presion:

- 8 shufër

- Fuqi:

- 10,9 kW (14,82 HP)

- Peshë bosh:

- 6 400 kg

- Tensioni hyrës:

- 400 V

- Peshë mbushëse (min.):

- 200 g

- Peshë mbushjeje (maks.):

- 5 000 g

Detajet e ofertës

- ID e shpalljes:

- A17231422

- Përditësim:

- së fundmi më 25.09.2025

Përshkrim

XFR 1000

Liquid Media Filling Line

A fully automated liquid media filling line featuring robotic capping, automated handle placement, dual-sided labelling, optical quality control, and pallet wrapping.

An end-to-end solution covering the entire process, from bottle blowing to the palletizing and wrapping of filled bottles.

XFR LIQUILOAD

It enables optimal filling speeds for bottles of varying characteristics and liquids of different viscosities.

The machine’s easy configuration for different bottle types and corresponding liquids ensures quick adaptation to market demands.

• Capability to increase the number of nozzles

• Nozzles designed to prevent foaming of the liquid

• 800 to 4,000 filled bottles per hour

• Servo-driven nozzle positioning

• Easy configuration of new programs

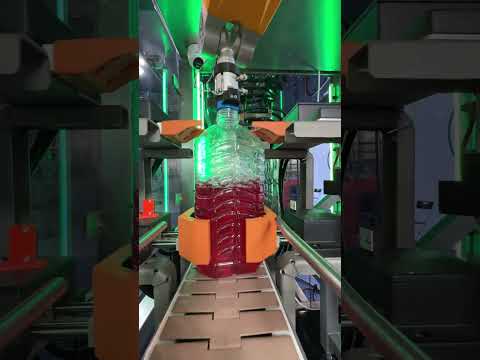

XFR BOTTLELOCK

The machine segment performs fully automated capping of filled bottles.

Designed to accommodate various cap types, simplifying machine adjustments for seamless operation.

• Cap type adaptability

• Robotic bottle capping

• Optical inspection

• 800 to 2,000 capped bottles per hour

XFR HANDLEGRIP

The automatic robotic placement of handles on bottles, while they move continuously towards the labeling machine, ensures seamless and uninterrupted operation.

• Adaptability to different handle types

• Robotic handle application on bottles

• Optical inspection for handle orientation verification

• Capability to attach handles with a funnel

XFR LABELFLOW

The machine applies the appropriate labels to both sides of the bottle, creating a finished appearance.

In the next phase, the labelled bottles undergo optical inspection.

Nksdouq Nv Tspfx Ab Asu

• HERMA labelling system

• Simplified label type changeover

• Servo-driven for enhanced labeling precision

• Monitoring of remaining labels with operator alerts

OPTIONAL PARTS:

1. OPTICAL INSPECTION

Industrial cameras with integrated lighting and pneumatic ejection system.

2. PICK AND PLACE ROBOT

6-axis robot equipped with a 160 kg gripper for the current handling of 8 bottles onto a Euro pallet.

3. PALLETIZING

Palletizer with automatic pallet feeding via a roller conveyor to the bottle stacking area.

4. PALLET WRAPPING

The automatic pallet wrapper applies stretch film to palletized products, securing them for easier and safer transport.

5. FINISHED GOODS STORAGE

Finished pallets are transported to the warehouse via a metal roller conveyor.

6. REMOTE CUSTOMER SUPPORT

We provide remote support to ensure optimal machine performance.

7. ADDITIONAL OPTIONS

Automated data integration with ERP systems; RFID login; NFC detection of parts and tools; magnetically mounted tools.

8. MACHINE CONFIGURATION

Segments can operate independently or as an integrated solution, depending on the client's specific needs.

Proton EE-Elektronika d.o.o.

MachinFlex d.o.o.

Liquid Media Filling Line

A fully automated liquid media filling line featuring robotic capping, automated handle placement, dual-sided labelling, optical quality control, and pallet wrapping.

An end-to-end solution covering the entire process, from bottle blowing to the palletizing and wrapping of filled bottles.

XFR LIQUILOAD

It enables optimal filling speeds for bottles of varying characteristics and liquids of different viscosities.

The machine’s easy configuration for different bottle types and corresponding liquids ensures quick adaptation to market demands.

• Capability to increase the number of nozzles

• Nozzles designed to prevent foaming of the liquid

• 800 to 4,000 filled bottles per hour

• Servo-driven nozzle positioning

• Easy configuration of new programs

XFR BOTTLELOCK

The machine segment performs fully automated capping of filled bottles.

Designed to accommodate various cap types, simplifying machine adjustments for seamless operation.

• Cap type adaptability

• Robotic bottle capping

• Optical inspection

• 800 to 2,000 capped bottles per hour

XFR HANDLEGRIP

The automatic robotic placement of handles on bottles, while they move continuously towards the labeling machine, ensures seamless and uninterrupted operation.

• Adaptability to different handle types

• Robotic handle application on bottles

• Optical inspection for handle orientation verification

• Capability to attach handles with a funnel

XFR LABELFLOW

The machine applies the appropriate labels to both sides of the bottle, creating a finished appearance.

In the next phase, the labelled bottles undergo optical inspection.

Nksdouq Nv Tspfx Ab Asu

• HERMA labelling system

• Simplified label type changeover

• Servo-driven for enhanced labeling precision

• Monitoring of remaining labels with operator alerts

OPTIONAL PARTS:

1. OPTICAL INSPECTION

Industrial cameras with integrated lighting and pneumatic ejection system.

2. PICK AND PLACE ROBOT

6-axis robot equipped with a 160 kg gripper for the current handling of 8 bottles onto a Euro pallet.

3. PALLETIZING

Palletizer with automatic pallet feeding via a roller conveyor to the bottle stacking area.

4. PALLET WRAPPING

The automatic pallet wrapper applies stretch film to palletized products, securing them for easier and safer transport.

5. FINISHED GOODS STORAGE

Finished pallets are transported to the warehouse via a metal roller conveyor.

6. REMOTE CUSTOMER SUPPORT

We provide remote support to ensure optimal machine performance.

7. ADDITIONAL OPTIONS

Automated data integration with ERP systems; RFID login; NFC detection of parts and tools; magnetically mounted tools.

8. MACHINE CONFIGURATION

Segments can operate independently or as an integrated solution, depending on the client's specific needs.

Proton EE-Elektronika d.o.o.

MachinFlex d.o.o.

Dokumente

Ofrues

Shënim: Regjistrohuni falas ose hyni, për të parë të gjitha informacionet.

I regjistruar që nga: 2020

Dërgo kërkesë

Telefon & Faks

+385 43 3... njoftime

Këto njoftime mund t'ju interesojnë edhe ju.

Njoftim i vogël

Brakel

Brakel

1 447 km

Presë letre

BTS-MF200MK Ballenpresse Waste Baler

BTS-MF200MK Ballenpresse Waste Baler

Njoftim i vogël

Jüri

Jüri

2 052 km

Debarker

Valon Kone OYVK-550-Combi 2R/480(620)

Valon Kone OYVK-550-Combi 2R/480(620)

Njoftim i vogël

Ostrołęka

Ostrołęka

1 330 km

Prodhimi i qumështit dhe produkteve të qumështit

MargoPasteryzator

MargoPasteryzator

Njoftim i vogël

Gjermania

Gjermania

1 340 km

Makinë për makarona

JuwelPQ6-SU/PQ3-SU

JuwelPQ6-SU/PQ3-SU

Njoftim i vogël

Bad Lippspringe

Bad Lippspringe

1 466 km

FURRA GRILLOMAX

GRILLOMAX GRILLSTATIONGRILLSTATION

GRILLOMAX GRILLSTATIONGRILLSTATION

Njoftim i vogël

Italia

Italia

638 km

Makinë për prodhimin e pijeve

Bottling Alfatek beerBottling Line Complete Bottling

Bottling Alfatek beerBottling Line Complete Bottling

Njoftim i vogël

Gjermania

Gjermania

1 340 km

Makinë për të bërë çanta

Honsel & Co.722

Honsel & Co.722

Njoftim i vogël

Breda

Breda

1 648 km

Linja tubash PVC WEBER DS 8.5 deri në 160 mm

WeberWEBER DS 8.5

WeberWEBER DS 8.5

Njoftim i vogël

Bielefeld

Bielefeld

1 495 km

Cutter cut expert ecocam 2 / Plotteri

expert international gmbhcut expert ecocam 2

expert international gmbhcut expert ecocam 2

Njoftim i vogël

Sevenum

Sevenum

1 572 km

Mbushës pulsi inline

KingKT340/ILKT

KingKT340/ILKT

Njoftimi juaj u fshi me sukses

Ndodhi një gabim