Mulliri prerës me shpejtësi të lartëZERMA

GST 250/450

Mulliri prerës me shpejtësi të lartë

ZERMA

GST 250/450

VB plus TVSH

18 100 €

Viti i prodhimit

2024

Gjendje

I ri

Vendndodhje

Brahlstorf

Fotot tregojnë

Shfaq hartën

Të dhëna për makinën

- Përshkrimi i makinës:

- Mulliri prerës me shpejtësi të lartë

- Prodhues:

- ZERMA

- Model:

- GST 250/450

- Viti i prodhimit:

- 2024

- Gjendje:

- i ri

Çmimi & Vendndodhja

VB plus TVSH

18 100 €

- Vendndodhje:

- Schützenstraße 7, 19273 Brahlstorf, Deutschland

Telefononi

Detajet e ofertës

- ID e shpalljes:

- A13548343

- Përditësim:

- së fundmi më 03.05.2025

Përshkrim

Optimization of an established concept.

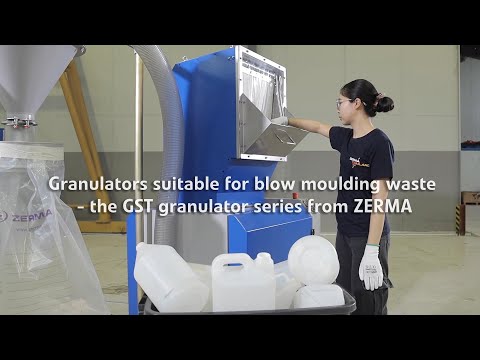

Shredding of large-volume blow-molded parts as well as start and end pieces

The best features of the proven GST and GSC series have been integrated into a compact redesign, with particular emphasis on weight, handling and energy efficiency.

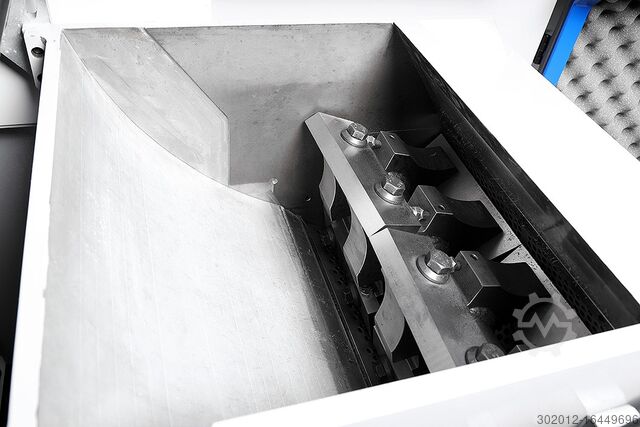

These compact granulators are equipped with complete sound insulation, resulting in extremely quiet operation. The granulators are available with 250 mm rotor diameters and widths of 300, 450 to 600 mm. The curved rear wall of the cutting chamber ensures aggressive material feed and prevents material jams. As with all ZERMA granulators, the rotor and stator knives can be adjusted outside the machine to reduce maintenance downtime.

The highly tangential, curved rear wall of the cutting chamber combined with the aggressive open rotor design ensures reliable material intake and minimizes the risk of blockages.

The compact granulators are suitable for use in blow molding operations. They are suitable for recycling voluminous parts such as bottles, canisters and crates. Due to the low feed height, the machines can be easily fed with material by hand or a small conveyor belt. The low noise emission and small footprint make the granulator the perfect solution for inline shredding

Optional rear wall with higher stator knife M version:

The feed method with a higher stator blade is better suited for thicker-walled and more compact parts, such as injection molded parts, profiles, sheets, etc. Due to the cutting geometry and the lower aggressiveness of the rotor, a high-quality regrind is achieved regardless of the material type or shape, e.g. injection molded parts, profiles, plates, etc.

Control system and control cabinet:

The integrated control and control panel not only complies with all applicable safety regulations, but can also be adapted to specific requirements. In addition, peripheral equipment such as feed conveyors, metal detection and unloading systems can be seamlessly integrated into the machine's control system. For improved efficiency, an optional intelligent energy saving function is also available, which reduces power consumption during idle times and can automatically start and stop the system based on the status of upstream machines.

Standard configuration with blower, power consumption 0.75 kW and 400 cyclone

Rotor diameter (mm) 250

Rotor width (mm) 450

Drive (kW) 7.5

Number of rotor blades 3 x 2

Number of stator knives 2

Screen perforation (mm) > 6

Weight approx. (kg) 700

Feed opening (mm) 380 x 450

Pjdpop Sr H Dofx Ad Regg

Opening feed option of the M version (mm) 295 x 450

Njoftimi është përkthyer automatikisht. Mund të ketë gabime në përkthim.

Shredding of large-volume blow-molded parts as well as start and end pieces

The best features of the proven GST and GSC series have been integrated into a compact redesign, with particular emphasis on weight, handling and energy efficiency.

These compact granulators are equipped with complete sound insulation, resulting in extremely quiet operation. The granulators are available with 250 mm rotor diameters and widths of 300, 450 to 600 mm. The curved rear wall of the cutting chamber ensures aggressive material feed and prevents material jams. As with all ZERMA granulators, the rotor and stator knives can be adjusted outside the machine to reduce maintenance downtime.

The highly tangential, curved rear wall of the cutting chamber combined with the aggressive open rotor design ensures reliable material intake and minimizes the risk of blockages.

The compact granulators are suitable for use in blow molding operations. They are suitable for recycling voluminous parts such as bottles, canisters and crates. Due to the low feed height, the machines can be easily fed with material by hand or a small conveyor belt. The low noise emission and small footprint make the granulator the perfect solution for inline shredding

Optional rear wall with higher stator knife M version:

The feed method with a higher stator blade is better suited for thicker-walled and more compact parts, such as injection molded parts, profiles, sheets, etc. Due to the cutting geometry and the lower aggressiveness of the rotor, a high-quality regrind is achieved regardless of the material type or shape, e.g. injection molded parts, profiles, plates, etc.

Control system and control cabinet:

The integrated control and control panel not only complies with all applicable safety regulations, but can also be adapted to specific requirements. In addition, peripheral equipment such as feed conveyors, metal detection and unloading systems can be seamlessly integrated into the machine's control system. For improved efficiency, an optional intelligent energy saving function is also available, which reduces power consumption during idle times and can automatically start and stop the system based on the status of upstream machines.

Standard configuration with blower, power consumption 0.75 kW and 400 cyclone

Rotor diameter (mm) 250

Rotor width (mm) 450

Drive (kW) 7.5

Number of rotor blades 3 x 2

Number of stator knives 2

Screen perforation (mm) > 6

Weight approx. (kg) 700

Feed opening (mm) 380 x 450

Pjdpop Sr H Dofx Ad Regg

Opening feed option of the M version (mm) 295 x 450

Njoftimi është përkthyer automatikisht. Mund të ketë gabime në përkthim.

Ofrues

Shënim: Regjistrohuni falas ose hyni, për të parë të gjitha informacionet.

I regjistruar që nga: 2023

Dërgo kërkesë

Telefon & Faks

+49 4181 ... njoftime

Këto njoftime mund t'ju interesojnë edhe ju.

Njoftim i vogël

Buchholz in der Nordheide

Buchholz in der Nordheide

1 562 km

Makinë grirëse

ZermaGST 250/450

ZermaGST 250/450

Njoftim i vogël

Zuzenhausen

Zuzenhausen

1 268 km

Mullinj anësorë

ZERMAGSL 300

ZERMAGSL 300

Njoftim i vogël

Buchholz in der Nordheide

Buchholz in der Nordheide

1 561 km

Trupi i zbrazët i mullirit prerës ZERMA GST250/450

ZERMAGST 250/450

ZERMAGST 250/450

Njoftim i vogël

Sieradz

Sieradz

1 168 km

Gjenerator

ProtonOasis 1

ProtonOasis 1

Njoftim i vogël

Zuzenhausen

Zuzenhausen

1 268 km

Granulatorët

ZERMARohr- und Profilschneidmühle GSP

ZERMARohr- und Profilschneidmühle GSP

Njoftim i vogël

Klundert

Klundert

1 670 km

Gjenerator

John DeereStamford 42.5kVA

John DeereStamford 42.5kVA

Njoftim i vogël

Erftstadt

Erftstadt

1 487 km

Makinë për mbushjen dhe mbylljen e qeseve

alpha-pack GmbHModell DEDAPHS-140S

alpha-pack GmbHModell DEDAPHS-140S

Njoftim i vogël

Berlin

Berlin

1 361 km

Mulli granulimi

Tria80-40 TE-SL

Tria80-40 TE-SL

Njoftim i vogël

Berlin

Berlin

1 361 km

Tuneli i tkurrjes

Quick-packTTN50

Quick-packTTN50

Njoftim i vogël

Sottrum

Sottrum

1 565 km

Traktor

JCBFastrac 4x4 Mulag Front Heck Mäher 8632 Stunden

JCBFastrac 4x4 Mulag Front Heck Mäher 8632 Stunden

Njoftimi juaj u fshi me sukses

Ndodhi një gabim